Introduction:

While this is an ongoing project, we have already made significant progress in the creation and design of the Robotic Exosuit. Currently, we are in production of the preliminary prototype and are researching sensors and human body dynamics in order to allow for increased lifting capacity amongst construction workers.

Main points:

Creating a motorized upper body exoskeleton to increase efficiency and decrease injuries amongst manual laborers

Able to be created and manufactured for under $2500 with sufficient durability and utility to be commercially viable

Primary developer of sensor system and human body modelling for exosuit, involving mechatronics, Chassis Design, Electonics, and robotics.

Robotic Exosuit Design

When our capstone team first sat down to tackle the idea of a robotic exosuit, the ambition was clear: build a wearable system that could assist manual laborers in lifting heavy objects, reducing strain and injury. But the path from concept to prototype was anything but simple. We were five engineers—three mechanical, two electrical—and we quickly realized that every one of us would need to stretch beyond our comfort zones. I volunteered to lead sensor development, knowing it would be one of the most complex and foundational parts of the system.

The challenge wasn’t just choosing sensors—it was designing a full feedback loop. Our exosuit needed to read a user’s motion and force, interpret that data in real time, and drive motors to assist accordingly. That meant building a system that could understand human biomechanics and respond with mechanical precision. I leaned into a concept called inverse dynamics, which allowed me to calculate the torque needed to counteract a user’s movement based on force input and limb geometry. It was a powerful framework, but it required accurate position data—something notoriously difficult to obtain in robotics.

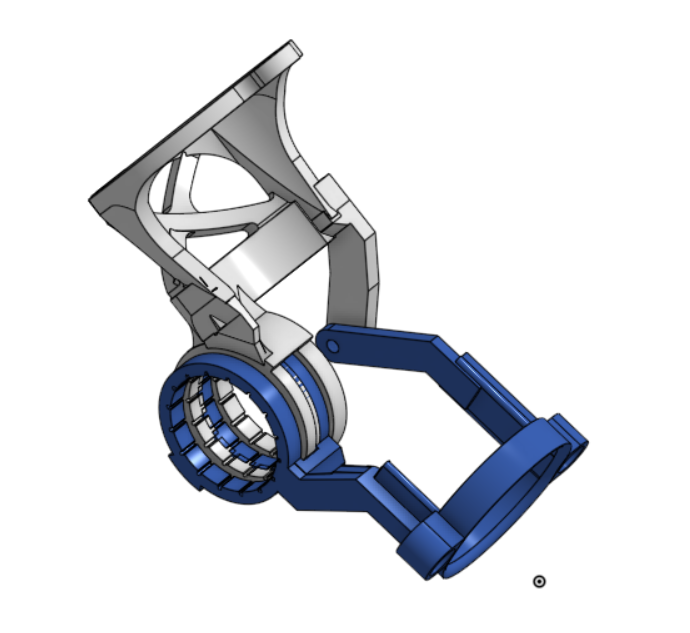

IMUs weren’t precise enough. So I turned to joint encoders. By measuring the angles of the shoulder and elbow, and knowing the length of the arm, I could triangulate the position of the hand. From there, I could calculate moment arms and apply torque where needed. It was the first time I’d built a sensor system from scratch, and it forced me to think through every layer of design: precision, cost, weight, user comfort, and manufacturability.

We started the project in mid-September, and by early October we had a low-fidelity prototype. That might sound modest, but for a hardware project built from nothing, it was a huge milestone. I took the initiative to CAD early versions of the wrist and elbow assemblies, knowing that seeing physical parts—even rough ones—would energize the team. And it worked. Once the first prints came off the machine, the mood shifted. What had felt like an abstract challenge suddenly became real. We weren’t just talking about building an exosuit—we were doing it.

The team dynamic transformed. What began as a hesitant, loosely organized group quickly became a focused, fast-moving unit. We set aggressive goals: two weeks for research, one month for a working prototype, and another month for a test-ready build. We didn’t hit every target perfectly, but the pace we set pushed us to treat the project like a full-time job. I found myself working eight-hour days on the exosuit, then turning to my other coursework at night. It was intense, but deeply rewarding.

By the time we hit our first major milestone, we had fabricated nearly 30 unique parts. Most were 3D printed, but we had already begun sourcing more durable materials for future iterations. We hadn’t yet integrated motors or sensors—shipping delays held us back—but the mechanical foundation was solid. We were ahead of schedule, and that gave us room to think bigger: more testing, better integration, and maybe even added features down the line.

One of the most satisfying wins came from refining our sensor selection. Early on, we considered buying a wide array of sensors, but through careful design and iteration, we narrowed our needs and saved roughly 10% of our budget. That decision wasn’t just about cost—it was about clarity. We were learning to build smarter, not just faster.

Looking back, the biggest lesson wasn’t technical—it was about leadership. In ambitious projects, someone always has to take the lead, even if they’re not officially in charge. Sometimes it’s the person who cares most. Sometimes it’s the one who sees the path forward most clearly. For me, it was about showing the team what was possible, getting them invested, and helping them believe in the project’s potential. Leadership, I’ve learned, isn’t about scheduling—it’s about vision. It’s about selling the idea, building momentum, and helping others see why it matters.

We’re still early in the journey, but the foundation is strong. The exosuit is taking shape, and with every part we print, every system we refine, we’re getting closer to something real—something that could make a difference. And for me, that’s what engineering is all about.

Cad of the Elbow Joint with adjustable length

Cad Of Wrist Sensor complex