RICE Eclipse

When I joined Rice Eclipse, I wasn’t stepping into a classroom—I was stepping into a full-scale engineering operation. With over a hundred students working across five specialized teams, it felt more like a startup than a university club. I was placed on the Aero team, responsible for the rocket’s structural and aerodynamic design. My assignment: develop the CAD model for the articulation guard, a protective shell around the rocket’s movable fins. It wasn’t the flashiest component, but it was essential. And for me, it was the first time I’d ever designed something that had to survive the sky.

The articulation guard had to do more than just exist—it had to perform. It needed to withstand high-speed airflow, temperature fluctuations, and pressure changes, all while allowing the fins to articulate freely. These fins were our rocket’s steering system, enabling mid-flight adjustments that could help us land closer to our target zone. That meant the guard had to be lightweight, low-drag, and heat-resistant, without compromising the rocket’s aerodynamic profile. I quickly learned that in aerospace, every gram and every curve matters.

At the time, I was a freshman with no experience in SolidWorks. I remember staring at the interface, overwhelmed, wondering how I’d ever turn a blank screen into a functioning part. But I wasn’t alone. My teammates—many of them upperclassmen—were generous with their time and knowledge. I asked questions constantly: how to model fluid flow, how to simulate deformation, how to calculate drag. Slowly, I began to understand not just the software, but the physics behind the rocket.

Our first prototype was 3D printed in PLA and TPU, materials we had easy access to in the Rice makerspace. But early tests revealed serious flaws. The printed structure contained internal air pockets that risked bursting under pressure. Worse, the materials couldn’t handle the heat—they warped, softened, and threatened to fail mid-flight. We pivoted quickly, switching to a solid print structure and eventually sourcing a heat-resistant filament with a molded plastic shell. It wasn’t perfect, but it was a major step forward.

As the design matured, we focused on reducing drag and weight. The original guard had a surface area of about 85 square inches. I redesigned it to bring that down to just under 53. At the same time, we cut the weight from around six pounds to just under four. These weren’t just numbers—they were performance gains. Less drag meant less stress on the fastenings. Less weight meant more altitude. And for the first time in our team’s history, the fins could articulate freely, giving us control during both ascent and descent.

The rocket itself launched to roughly 26,000 feet and successfully recovered its payload. I wasn’t there for the final launch—I had left campus for the summer—but I followed the results closely. Knowing that my design had contributed to that success was deeply rewarding. It wasn’t just about the part I built—it was about the system I helped improve.

Rice Eclipse was a massive, multidisciplinary effort. We had teams for propulsion, fluids, software, electrical, and aero, each with 10 to 20 members. The Aero team, where I worked, had to coordinate constantly with the others. We had a budget, but it was tight. Every material request had to be justified. Every design had to be manufacturable with the tools we had—mostly 3D printers and a water jet cutter. And everything had to be done by the end of spring semester, in time for the competition in May.

Looking back, the articulation guard taught me more than just CAD modeling. It taught me how to design under pressure—literally and figuratively. It taught me how to collaborate across disciplines, how to iterate quickly, and how to think critically about materials and constraints. I didn’t revolutionize the team’s design philosophy, but I did contribute meaningfully to a successful launch. And I carried those lessons forward into every engineering challenge I’ve faced since.

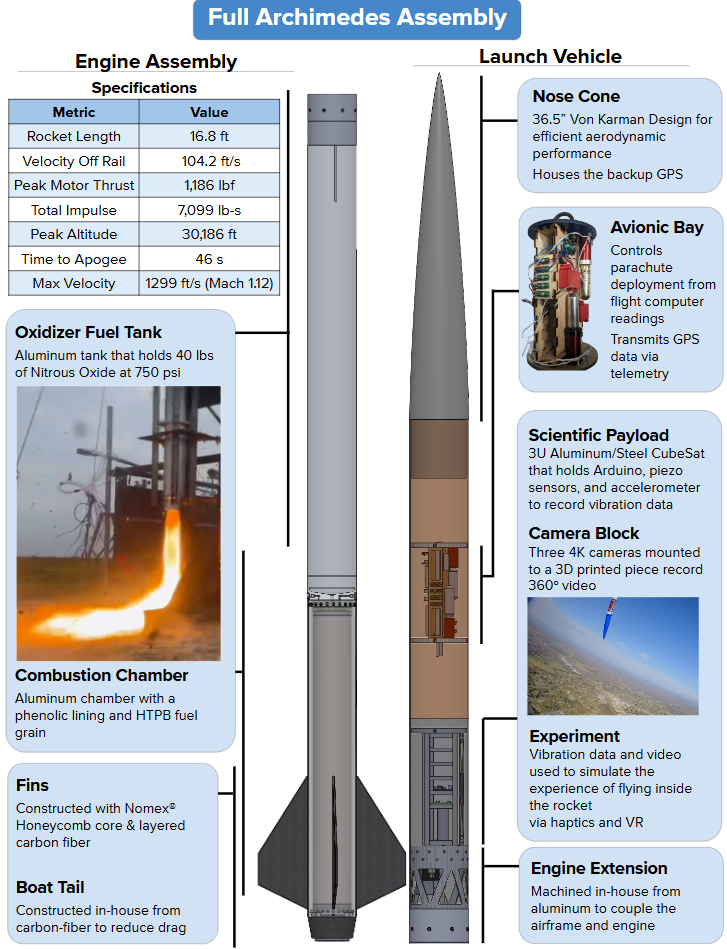

Archimedes Launch